Choosing the Right Outrigger Pad Material: Wood, Steel, or Custom Composite

May 14, 2025

Selecting the right outrigger pad for the job

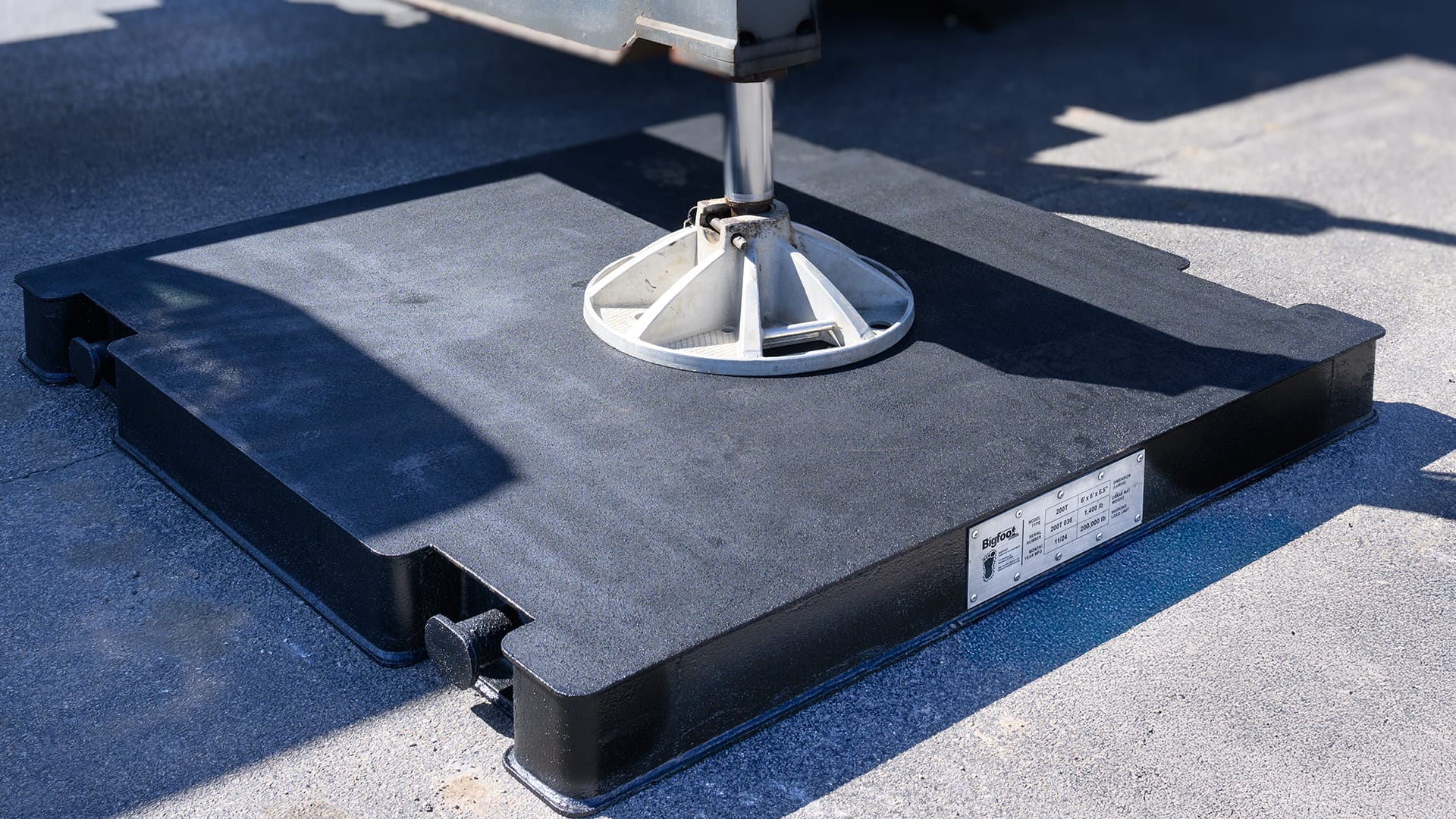

As an American manufacturer of high-quality outrigger pads, Bigfoot understands the importance of selecting the right outrigger pad material for different job site needs. The three primary materials used for outrigger pads—wood, steel, and custom composite—each offer unique advantages, depending on the application. In this post, we break down the strengths of each material to help you determine the best choice for your specific needs.

Wood Outrigger Pads

Strengths:

- Lightweight and easy to handle

- Cost-effective solution for many applications

- Natural flexibility helps distribute weight evenly on softer ground

Best Use Cases

Wood outrigger pads are ideal for applications where affordability and ease of transport are priorities. They are commonly used in utility work, with light-duty cranes, and for short-term projects where heavy-duty support isn’t required. However, wood can degrade over time due to moisture and weather exposure, making it less suitable for long-term or high-load applications.

Steel Outrigger Pads

Strengths:

- Extremely strong and capable of handling high-capacity loads

- Ideal for heavy cranes and industrial applications

- Resistant to wear and deformation under extreme pressure

Best Use Cases

Steel outrigger pads are the go-to choice for heavy equipment and high-load applications such as large-scale construction projects and industrial lifting operations. They perform exceptionally well on firm ground surfaces like compacted gravel and concrete. However, their weight makes them more difficult to transport, and they can sink into softer ground without proper load.

Custom Composite Outrigger Pads

Strengths:

- High strength-to-weight ratio, offering durability without excessive weight

- Resistant to water, chemicals, and extreme weather conditions

- Long-lasting and low maintenance compared to wood and steel

Best Use Cases

Custom composite outrigger pads provide the best balance of strength, durability, and ease of handling. They are perfect for a wide range of applications, from general construction to utility work and high-load lifting environments. Their resistance to moisture and chemicals makes them ideal for wet or corrosive environments where wood and steel may fail over time.

Choosing the Right Material for Your Needs

| Material | Strengths | Best For |

|---|---|---|

| Wood | Lightweight, cost-effective, flexible load distribution | Short-term, light-duty applications, utility work |

| Steel | High load capacity, durable, industrial-grade strength | Heavy cranes, large-scale construction, industrial sites |

| Custom Composite | Strong yet lightweight, weather and chemical-resistant | Versatile applications, long-term durability, wet conditions |

Conclusion

Selecting the right outrigger pad material is crucial to ensuring stability, safety, and efficiency on the job site. While wood provides an economical and lightweight option, steel offers unmatched strength for heavy loads, and custom composite pads deliver the best combination of durability, strength, and versatility. At Bigfoot, we offer high-quality outrigger pads in all three materials to suit your specific needs. Call us today at 888-743-7320 to find the best solution for your equipment and job site conditions!

References

- American Society of Mechanical Engineers (ASME) – Load Handling Guidelines

https://www.asme.org/codes-standards/find-codes-standards/p30-1-planning-load-handling-activities - Occupational Safety and Health Administration (OSHA) – Crane and Derrick Safety Standards

https://www.osha.gov/cranes-derricks/standards - Association of Equipment Manufacturers (AEM)

https://www.aem.org/