Outrigger pads are used with the outrigger system or down jack on your equipment. It is worth knowing about a few different systems of equipment for the outriggers or down jacks.

Out & down outrigger system: This is vertical pressure from the equipment & has a rubber up method. This system is designed to widen the footprint of the equipment, getting the rubber or tires up to make sure the PSI is not addressed through the suspension of the equipment but through the outrigger system.

The A-frame or 45-degree outrigger system: Smaller cranes or boom trucks have this style, as well as quarter mount equipment with a kicker leg being the 45-degree outrigger.

Combo of out & down with 45-degree outrigger systems on 1 unit.

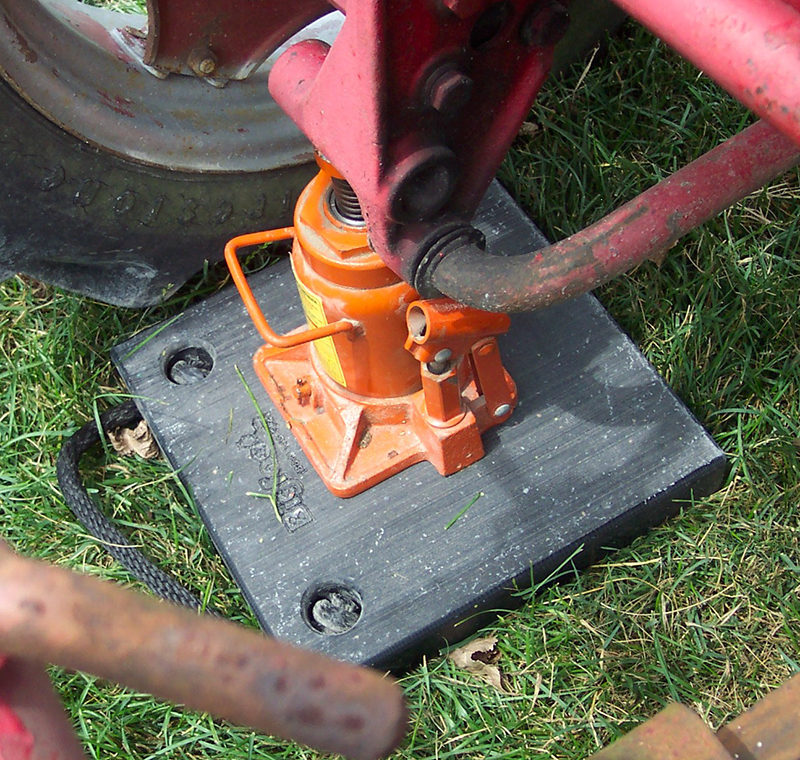

Down Jacks: This system is common for the trucking & RV industry with lowering gear for the down jacks to drop a trailer or set up level.

*Always follow the manufacturer’s recommendations of the equipment you are using or operating for set up.

Outrigger Pads are a Tool of Safety

50% of crane failure includes collapse from improper use of outriggers. The outrigger pad is used to displace the point of contact pressure PSI/ PSF that the ground sees.

The outrigger pad expands & displaces the point of contact from the equipment’s outrigger/ pontoon/ shoe/ float. This will decrease the PSI or PSF for the GBC (ground-bearing capacity). The GBC is the maximum PSI or PSF the ground can hold before it displaces. The point of contact on the equipment is small with exceptionally high PSI using outrigger pads to hold up & displace the PSI by expanding the point of contact to the ground.

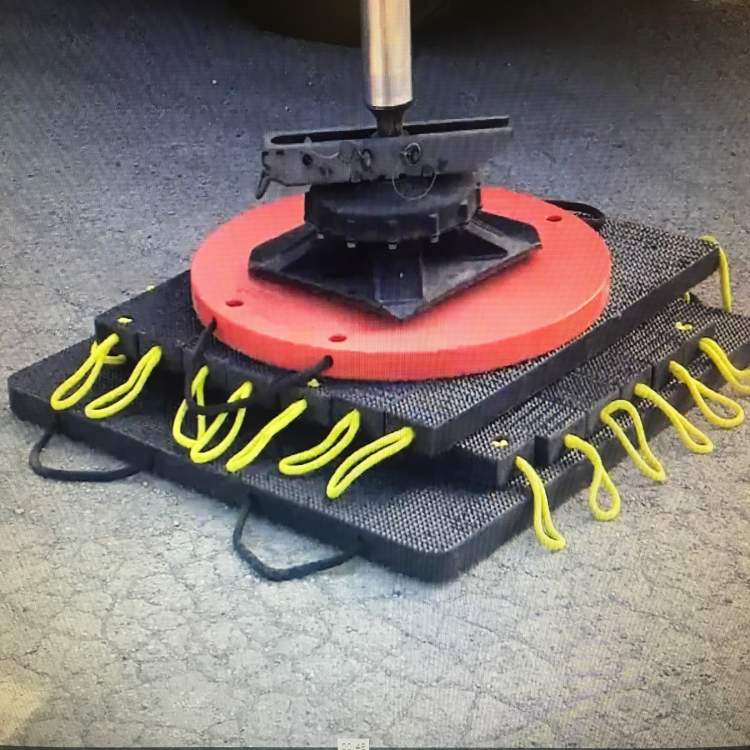

These portable and user-friendly outrigger pads are American made by American Veterans and our custom composite is guaranteed for life.

The reason for our Bigfoot name is that our outrigger pads make a BIG FOOT print or expand the point of contact from your equipment’s outrigger. The Bigfoot outrigger pads are an engineered tool for safety & success. The custom composite outrigger pads were built by Bigfoot Bill, working with engineers to get the maximum PSI value and guarantee these pads for life.

Stability is dependent on the equipment’s footprint and center of mass. The footprint is the total area enclosed by the support structures of the equipment. The center of mass is the point at which the equipment would balance if it were set on top of a single point of support. If the center of mass is off the edge or outside the footprint, the equipment will topple.

There are two ways to provide extra stability:

- Use a counterweight to help shift the center of mass back over the footprint.

- Make the footprint bigger.

All cranes have counterweights, but there is a limit to how heavy they can get for transportation and setup. The ground can only carry a certain PSI/ PSF before it will displace or collapse.

Using retractable outriggers to extend the footprint is essential for the crane’s stability. After deploying the equipment’s outrigger system, using Bigfoot outrigger pads to expand the point of contact will displace the PSI/ PSF for the GBC.

The materials Bigfoot uses are the highest quality with our American custom composite or Premium Birch.

- The custom composite is 1/7 the weight of steel with comparable PSI values to high-grade American steel. This material is exceptionally resistant to water/ electricity/ corrosion and guaranteed for life.

- The Premium Birch has been used in the field for decades in the harshest conditions with exceptional results. This has a typical life span of 10 years with normal conditions & setup.

WORTH KNOWING: BIGFOOT STRONGLY RECOMMENDS NOT USING FRP OR NON-AMERICAN MATERIALS ON ANY CRITICAL LOADS OR PICKS OF 10,000 LBS+ OR WITH PERSONNEL ALOFT.

Fiberglass/ FRP material outrigger pads or crane mats:

This material will give no visual indicators before or during the use of failure. Fiberglass/ FRP is for lightweight usage and has no place for the high PSI values that are seen with cranes or bucket trucks in any critical lift.

The use of Fiberglass has had to reduce its load ratings by 40%+ with real field conditions and use in a very short time. While reducing the load rating, they are still punching holes in Fiberglass for lightweight use. Fiberglass has no place in the real field for use on setup or supporting cranes or any equipment in a safe or secure manner.

Fiberglass or FRP is as follows:

- Will have brittle failure with no warning, even with inspection prior to use or set up.

- Poor strength will crush or punch holes in it

- Exceptionally expensive to repair

- Low life span with heavy loads & small point of contact. Our study with this has found failure within 1-2 years with exceptionally poor results in the field.

- As Fiberglass is used, the impact will break down and then with no warning collapse/ punch holes/ have complete failure.

Non-American materials: Bigfoot has had multi-non-American custom composite 3rd party tested. The results have been a 25% PSI value of our American custom composite.

There are companies that claim made-in-America while using non-American materials. Having material made outside the USA and then sold here as a vendor or marketing company is not made in America.

100% recycled material has nowhere near the strength of our custom composite. The recycled material is too inconsistent to give accurate PSI values, nor will it hold over time under the high comprehensive loads seen in this industry.